Nestlé Purina Hungary dry food plant design 1.

Nestlé Purina Hungary's pet food plant is located not far from Szombathely, in Bük, which can be basically divided into 3 main parts in terms of area and timeline.

The newest and largest greenfield investment project in the northern part of the site, with production and logistics halls, called Turul, is responsible for the production of wet petfood.

The smaller, recently constructed first wet manufacturing plant and office building is located on the southern side of the site.

The third dry animal feed plant, which is part of the Balaton project, is located between the two factories and was designed by M Mérnöki Iroda Kft.

Nestlé Purina Hungary dry food plant design 3.

During the planning phase, the challenges included the alignment of existing and new buildings, the integration of existing and new technologies into a single, functioning factory complex. The strict zoning rules used in the food industry (Basic and Medium Hygene Zones) had to be adhered to, while at the same time fire separated units had to be designed, independent of the existing building parts. The integration of raw materials of different weights, combustibility classes and batches into the production and logistics chain, the design of the premises and their feasibility in terms of size, was a challenge for the experts due to the small and limited space available.

Our tasks included the monitoring of the construction in the framework of an on-site visit. During such a site visit we were confronted with perhaps the most difficult part of the whole project, since (which of course had to be taken into account in the planning) the continuous operation of the existing factory building had to be ensured during the implementation of the project. During the demolition and construction works, the work areas had to be secured in such a way that this did not cause problems in the production areas, with some of the works having to be carried out in tight time frames and restricted areas.

Many engineering solutions were needed that were unconventional and had to be devised in just a few hours from the time the problem was discovered - which we are proud to say we managed.

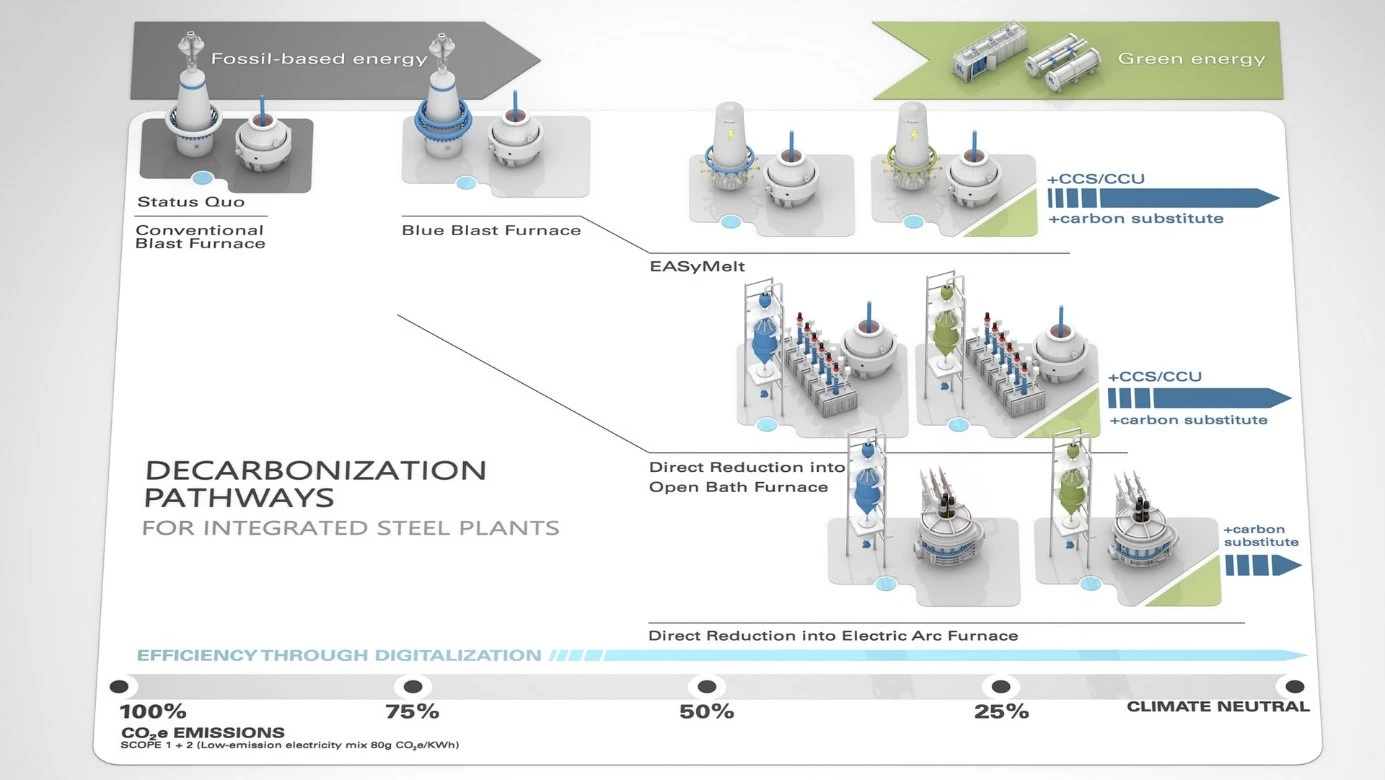

On the path to carbon-neutral steelmaking

Thyssenkrupp is Germany's largest steel manufacturer with nearly 26,000 employees and an annual production of 11 million tonnes of crude steel. Recognising the environmental impact of conventional steelmaking, Thyssenkrupp is moving towards sustainable, carbon-neutral steelmaking with the tkH2Steel® concept. By 2045, steel production will be exclusively powered by natural gases and hydrogen, ushering in a new era of sustainable steelmaking.

M Mérnöki Iroda Kft. is one of the design offices involved in the design process of the new plant. Keeping in mind the customer's needs and the technological challenges, we are honoured to be part of the advancement of carbon neutral steelmaking.

Cella Septichora - World Heritage Site in the heart of Pécs

The Cella Septichora in Pécs is famous not only among locals but also among tourists. The heritage building was completed in 2006 and has been attracting thousands of visitors over the years.

Unfortunately, the building has leaked in several places. The aim of our project was to find the source and the exact location of these leaks and then offer a solution. The building is completely below ground level, which made the task particularly difficult. The remains and archaeological finds left in the ground during the excavations also posed an additional challenge. The building required a number of innovative and unusual solutions, as we could not change the character and appearance of the building.

One of the main attractions of the Cella Septichora is the ruins of the seven-armed church. The original designer decided not to enclose this spectacle underground, but to design a glass ceiling of almost 400 m2 over it. It was the glass ceiling and its surroundings that were most exposed to the ingress of water. The glass ceiling is supported by a steel support structure, which is suitable for both pedestrian and vehicular traffic. Unfortunately, the seals of the glass structure failed due to heavy use and significant surface thermal expansion. A further complicating factor was that the joints between the glass panels were of different dimensions.

As the building is located at the foot of the mountain, various drainage systems were used to drain surface water before it reached critical points.

Traces of infiltration were visible in the interior spaces, which were aesthetically disturbing and required a solution. In these spaces, exposed concrete surfaces were created. The client did not want to change the look and feel of the concrete, so we used a chemical compound to remove the signs of soaking. The fair-faced concrete surfaces were treated with a water-based laitance to give a uniform finish, while leaving the character and texture of the concrete unchanged.

The design involved many more man-hours than anticipated and included in our contract, but we are delighted to have been able to help restore such a significant heritage building in Pécs.

After the completion of the project, we took part in a guided tour in Cella Septichora

Nestlé Purina Hungary dry food plant design 2.

The extensions and modifications to the dry plant covered an area of nearly 12,000 m2: a 36m high steel silo tower, a 38m high Process tower and a 42m high second mill tower were added to the existing 32m high steel structure mill tower, which is made of reinforced concrete up to 20m high and steel structure above.

In addition, new warehouses (750 m2) have been built to meet logistical needs, and a nearly 1,000m2 electrical and mechanical building extension has been completed to meet increased electrical and mechanical needs. These were mixed reinforced concrete and steel structure hall buildings, typically less than 20m in height, taking into account the connected buildings and the possibilities.

The project was exceptionally difficult and complex, both in the design and construction phases.