Final touches at the Schaeffler plant in Szombathely

The Schaeffler plant in Szombathely will be handed over soon. The picture taken with a drone shows that almost all the elements are in place, with only minimal work left to be done.

The project consists of several building sections, including the logistics hall and the office and social block. An ornamental garden has also been completed, which will also be beautiful when it blooms in spring.

Surányi Apartment Building

A new project has given us an opportunity to carry out a different design task for the Surányi Apartment Building. Located in one of the most beautiful parts of Pécs, we had to take into account several aspects of the building's design to meet all the possible needs of the future residents.

The four apartments have different proportions, so their design is unique. It was important to us that the apartments were modern, comfortable and spacious at the same time. During the design process we also carried out interior design tasks.

Which one do you like best?

Schaeffler E-mobility project

Schaeffler AG is one of the leading companies in the automotive and industrial sector and a major actor in the global market. The Group, which has a history of more than 70 years, was the first company in Hungary to start manufacturing purely e-mobility components and systems as well as electric motor components at its site in Szombathely. The project was handed over in September 2021.

The video below shows the premium quality interior glass wall and partition systems of Schaeffler Savaria's new plant in Szombathely. The video was made thanks to SIMOG GROUP Kft.

M Mérnöki Iroda Kft. carried out the architectural, structural and general design of the Schaeffler E-mobility project.

Schaeffler plant in Szombathely

The latest extension to Schaeffler's Plant 1 in Szombathely will soon be handed over, and even now, before the finishing touches have been put on, it already looks impressive. On the site visit before the handover we had the opportunity to see the plans come to life.

The project consists of several building sections, including a logistics hall and office and social blocks. The picture here is taken from the entrance of the social block. An ornamental garden has also been completed, which will also be beautiful when it blooms in spring.

We are looking forward to the handover, when all the details will be in place.

What makes steel production carbon neutral?

In our previous post, we briefly described how the German company Thyssenkrupp is making a major effort to make steel production sustainable by 2045.

But how will they do this?

The answer: tkH2Steel®

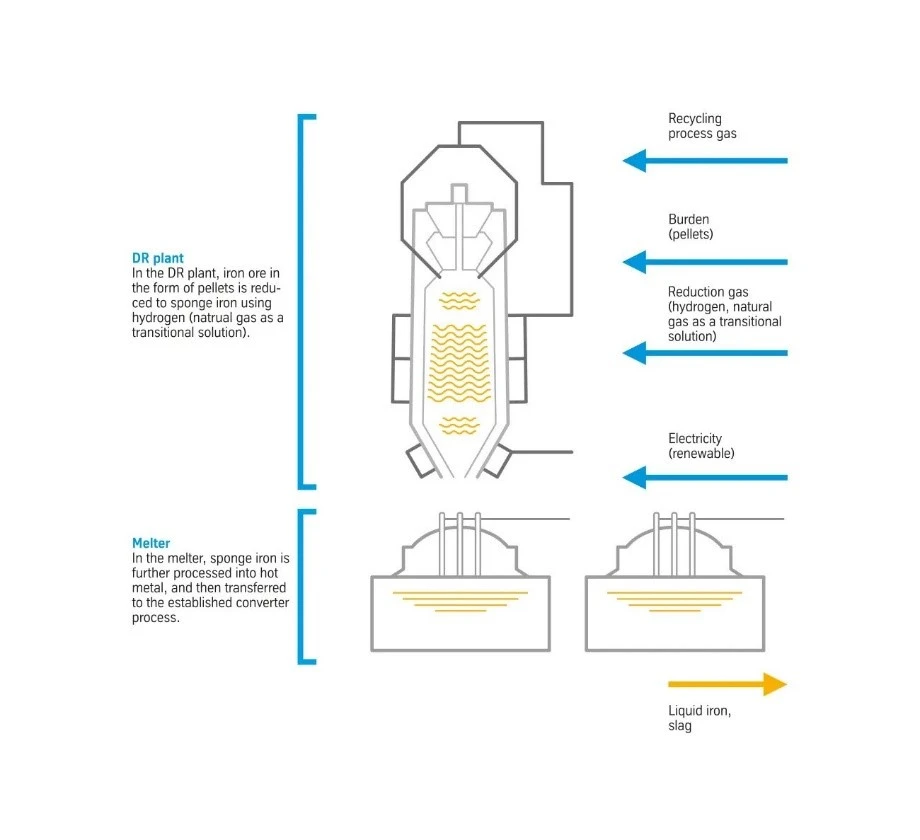

The direct reduction plant is a shaft furnace that operates on natural gas or hydrogen, and therefore does not require coal. At about 1,000 degrees Celsius, oxygen is removed from the iron ore, and direct reduced sponge iron (DRI) is produced. While still hot, the DRI is further processed into liquid hot metal in electrical power-operated melters. Positioning the two melters immediately adjacent to the direct reduction plant allows the solid input stock produced there to be converted into molten hot metal immediately; this makes the entire process particularly efficient. The plant with the two melters will be optimally integrated into the surrounding steelworks infrastructure.

Each year, the first plant will be able to supply 2.3 million metric tons of liquid hot metal (produced from 2.5 million metric tons of DRI) to the integrated BOF meltshops at the site, which will then process it into the proven steel grades. Thyssenkrupp will offer the full range of premium steel grades in decarbonized form in the long term; this will be a key factor in industrial value creation and thus a driver of the energy and mobility revolution, for example.

This new technology poses significant challenges for both designers and contractors. The so-called DR plant is a 150 m high steel-framed high tower building with a central plant weighing more than 5000 tonnes. We are proud that the design of such a major structure is carried out in our office.